WHAT IS REVERSE ENGINEERING

Engineering is the profession involved in the design, manufacture, construction and

maintenance of

products, systems or structures. Of which there are two types of engineering: forward

engineering and

reverse engineering.

Engineering is the traditional process of moving from high level abstraction and

logical designs of implementations to a physical system or part. Though in some situations

there may be a physical part, but without any technical details, drawings, assembly

details, material lists and engineering data.

The process of duplicating an existing component, product or subassembly without

the aid of drawing or documentation is known as reverse engineering.

Reverse engineering can be considered as the process of analysing to:

Identify system components and their integral relationship

Create representations of the system, or part in another form.

Create the physical representation of the system or part.

Reasons for reverse engineering a part or products

The original manufacturer of the product no longer produces it

There is inadequate documentation of the original design

The original manufacturer no longer exists, but the part is still required

The original design document never existed or was lost

Some bad features of the part should be designed out. For example, excessive wear

can indicate if a product should be improved

To strengthen the good characteristics of a part based on the usage

To explore avenues to improve the products performance, functionality and durability.

To acquire list of spare parts required for maintenance, that the original supplier

may not offer.

To update obsolete materials or antiquated manufacturing processes with more up to

date and less expensive methods of part manufacturing.

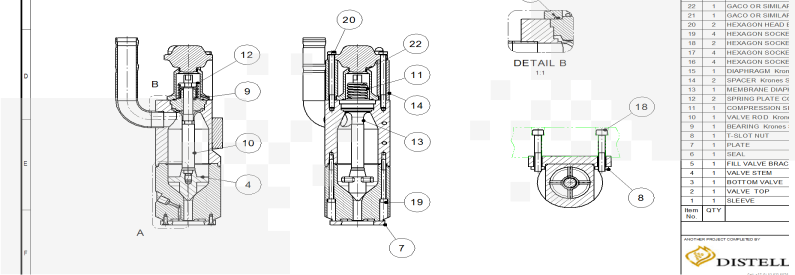

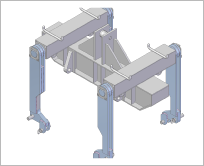

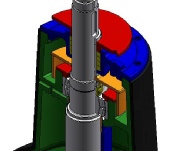

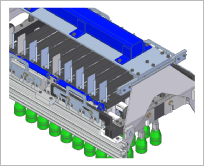

Reverse engineering allows the duplication of an existing part in capturing the physical

dimensions of the component, the characteristics and properties of materials.

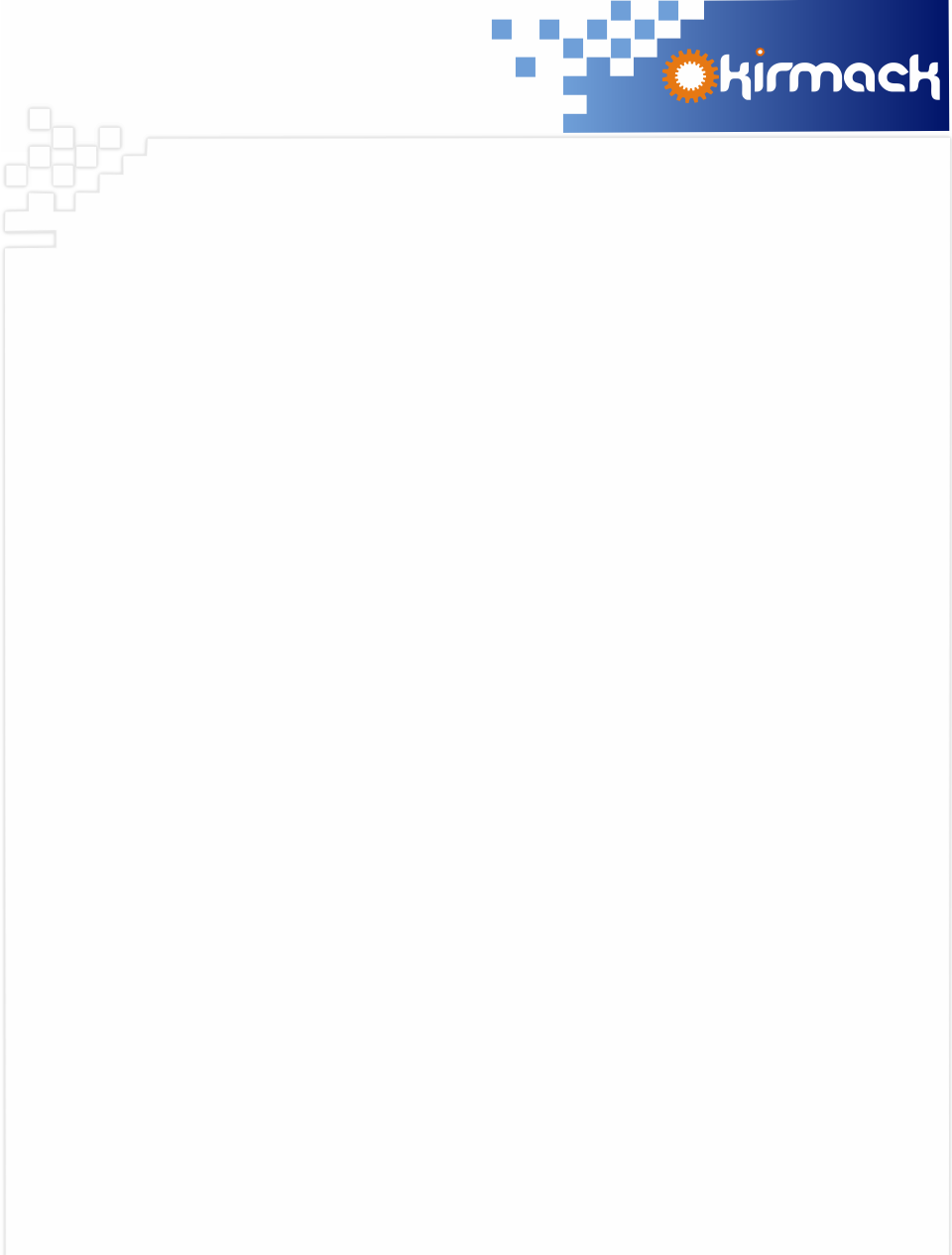

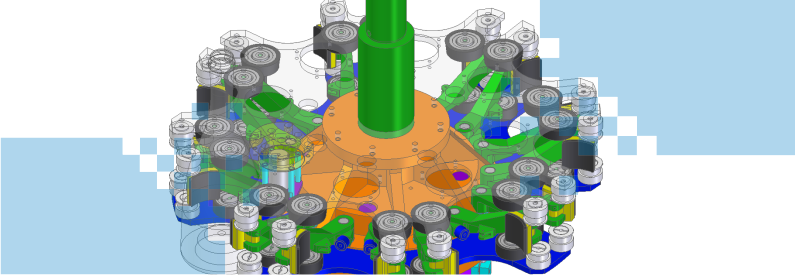

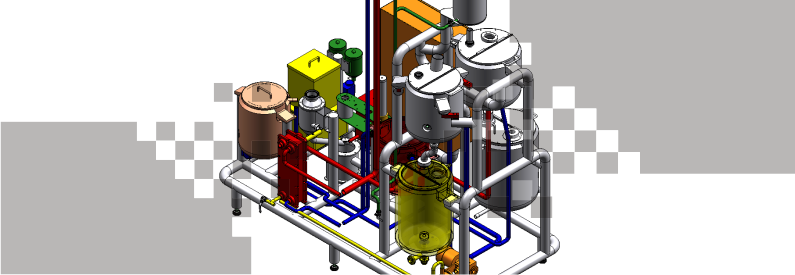

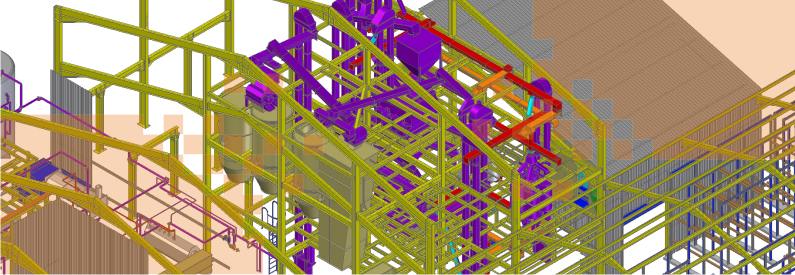

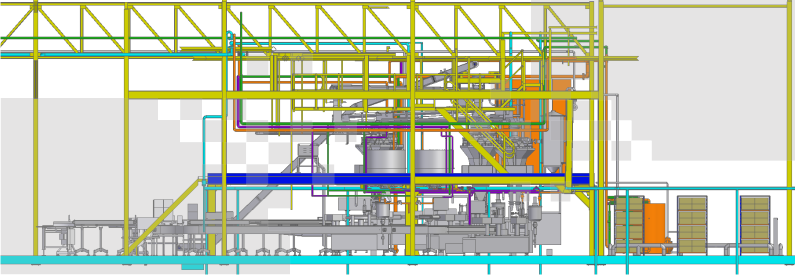

Our designers are skilled in creating 3D models, manufacturing drawings and generating

manufacturing data from any given physical products / components or assemblies